Nylon as a building block for transparent electronic devices?

Scientists at the Max Planck Institute for Polymer Research (MPI-P) led by Dr. Kamal Asadi have solved a four-decade-long challenge of producing very thin nylon films that can be used in electronic memory components, for instance. The thin nylon films are several hundred times thinner than a human hair, and could thus be attractive for applications in bendable electronic devices or for electronics in clothing.

As the microelectronics industry shifts toward wearable electronics and e-textiles, researchers are integrating electronic materials such as ferroelectrics with textiles. Nylons, a family of synthetic polymers, were first introduced in the 1920s for women's stockings, and are today among the most widely used synthetic fibers in textiles. They consist of a long chain of repeated molecular units, i.e. polymers, in which each repeat unit contains a specific arrangement of hydrogen, oxygen and nitrogen with carbon atoms.

Nylons also exhibit so called "ferroelectric properties." This means that positive and negative electric charges can be separated, and this state can be maintained. Ferroelectric materials are used in sensors, actuators, memory and energy-harvesting devices. The advantage in using polymers is that they can be liquified using adequate solvents and therefore processed from solution at low cost to form flexible thin films which are suitable for electronic devices such as capacitors, transistors and diodes. This makes ferroelectric polymers a viable choice for integration with e-textiles. Although nylon polymers have significant commercial applications in fabrics and fibers, their application in electronic devices has been hindered because it was impossible to create high-quality thin films of ferroelectric nylons by solution processing.

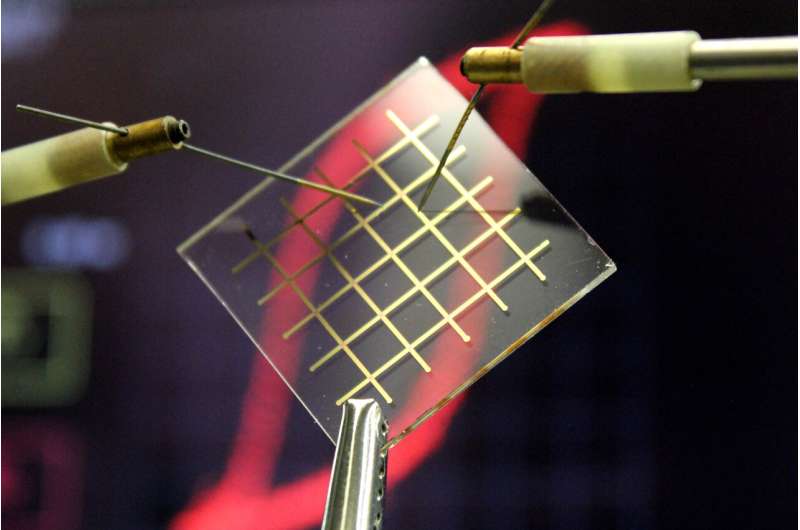

Scientists at the MPI-P, in collaboration with researchers from the Johannes Gutenberg University of Mainz and Lodz University of Technology, have now solved this 40-year-old problem, and developed a method to fabricate ferroelectric nylon thin-film capacitors by dissolving nylon in a mixture of trifluoroacetic acid and acetone and solidifying it again in vacuum. They were able to realize thin nylon films that are typically only a few 100 nanometers thick, several 100 times thinner than human hair. "Using this method, we have produced extremely smooth thin films. This is very important, because it prevents electrical breakdown of, for example, capacitors, and thereby destroying the electronic circuits. At the same time, the smoothness allows for developing transparent thin films and eventually, transparent electronic devices," says Dr. Kamal Asadi, group leader at the MPI-P.

By using their newly developed method, the group around Kamal Asadi was able to produce high performance nylon capacitors. The scientists subjected the prototypes of the capacitors to extended stress cycles and demonstrated robustness of ferroelectric nylons under millions of operation cycles. The thin nylon films could become an important component for use in flexible electronics in the future and find applications in bendable electronic devices or for electronics in clothing. These new findings pave the way toward multi-functional fabrics that serve as cloth for covering our body and at the same time can generate electricity from our body movement.

Their results have now been published in the journal Science Advances.

More information: "Solution-processed transparent ferroelectric nylon thin films" Science Advances (2019). DOI: 10.1126/sciadv.aav3489 , advances.sciencemag.org/content/5/8/eaav3489

Journal information: Science Advances

Provided by Max Planck Society